If you are looking for a cost-effective, quick method of creating custom t-shirts, cards and furnishings, silk screening is the right option. There are other methods to make these, like digital printing, but that costs more and takes longer than this method. We have compiled everything you need to know about Silk Screen Printing to try it out at home!

NEW SILK SCREEN STARTER SET - PAPER

BUY SCREEN PRINTING KITS FOR PAPER

LEARN MORE ABOUT THE DERIVAN PAPER SCREEN PRINTING KIT

NEW SILK SCREEN STARTER SET - FABRIC

BUY SCREEN PRINTING KITS FOR FABRIC

LEARN MORE ABOUT THE DERIVAN FABRIC SCREEN PRINTING KIT

WHAT IS SILK SCREEN PRINTING?

Screen printing essentially involves "pushing" ink through a screen over a stencil. Silkscreens were initially made, as the name suggests, from silk cloth. These days you will find most frames are stretched with synthetic materials. However, the process remains the same. The cloth or mesh is stretched over and fixed to a frame (usually wood, sometimes plastic or aluminium).

In printing, ink is dragged across the screen with a stiff piece of rubber known as a squeegee. The ink dragged across the screen, and it is pushed through the holes between the fibres of the screen and onto the surface below. The amount of ink deposited on the screen is largely determined by the mesh size of the screen (the mesh size refers to the number of holes per square inch).

HOW DO I GET MY DESIGN ONTO THE SILKSCREEN?

A stencil blocks out areas where the colour is not wanted. This stencil can be as simple as a piece of paper or plastic with a design cut out of it or, if longer print runs are required (paper stencils are generally only suitable for a few prints), special block out solutions are used. Derivan drawing fluid brushed directly onto the areas to be blocked out. And once dry, apply the derivan "blockout" medium - leaving it to dry and washing out the drawing fluid. Each form of "stencil" has its merits and limits. . It is essential to ensure the silkscreen Blockout or stencil system to be used is compatible with water-based products.

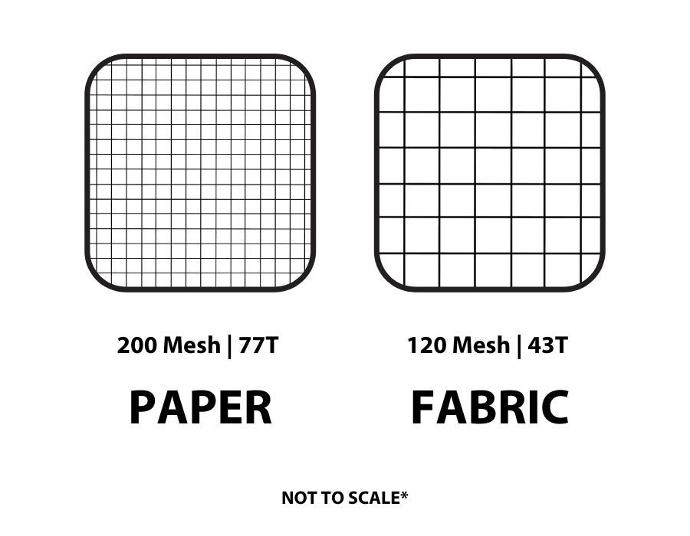

WHAT SILKSCREEN MESH SIZE SHOULD I USE?

Generally speaking, the best mesh size for fabric printing is 43T (monofilament). A coarser mesh screen is required for fabric than for paper; more ink is needed as the fabric tends to be more absorbent. If you are printing on paper, especially if it's a very detailed design and it is all about the details, you need a higher T rate, so a 77T *finer screen is required

Derivan Screen Printing Frames

SILKSCREEN PRINTING ON FABRIC

Choice of Fabric to silkscreen on?

Best results are obtained from absorbent fabrics; avoid waterproof materials as they inhibit penetration and repel the water-based colours. Fabrics containing starch, size, fillers, softeners or crease-proof treatments should be washed before printing. Fabrics containing waterproofing treatments may not accept the paints and may result in mottling, poor colour adhesion or patchy printing and may not remain wash proof.

SILKSCREEN PRINTING ON PAPER

Derivan Acrylics are perfectly suited to silk screen printing on paper directly out of the jar. The Derivan Acrylics Formula is a thick-bodied paint that adapts nicely for printing. You will first notice when using acrylics for silk screen printing is their quick drying time. This, coupled with the fact that only a thin layer of paint is left in the screen after each print, can lead to the paint drying in the screen. Acrylics dry water fast so they cannot be removed. One way to avoid "drying in the screen" is to use derivan Print Gel which will slow the drying time of the paint and allow the screens to be washed out more easily. Looking for a Paper Screen Printing Kit?

Silk Screen | Print Paste

HOW TO USE DERIVAN PRINT GEL

Start by mixing thoroughly equal parts of print paste and acrylic. As different colours will have different rates of opacity, each colour may require a different ratio of print paste.

This mixture can be stored for many months in an airtight container. However, do not put leftover ink back in the container as this may cause contamination. Brilliant transparent prints can be achieved using small amounts of paint with the print paste.

If a longer drying time is required, it is possible to add up to 5% Derivan Drying Retarder to the mix. This should only be necessary in the driest of climates.

CLEAN UP DERIVAN PRINT GEL

Wash up in lukewarm water with soap if necessary. If the ink dries on the screen, soak the screen overnight in soapy water and using a soft brush, clean the screen. The ink should dissolve easily.

There is no need to buy a second set of colours for silk screen printing on paper. Add the print paste to your existing acrylic range to produce a range of printing inks. The addition of the print paste slows the acrylic drying time, allowing the screens to be washed out easily.

The print paste allows the reduction of the colours to achieve transparent layering and brilliant, bright colours.

Using print paste with acrylics also means no toxic fumes to be dealt with and no waste solvents. Everything can be washed up in the water, and the waste poured into the garden.

SILKSCREEN PRINT HEAT SETTING

Paints used in fabric printing require heat fixing to become wash proof. Any type of heat can be used for this purpose. Heat tunnels or ovens may be used, but the most common form of heat fixing is the use of household iron. The main points to be observed are:

Ensure your design has completely air dried before it is heat fixed.

Apply heat evenly and continuously for the required time over the image when heat fixing.

Be sure not to scorch or burn the image or garment by keeping the iron moving constantly. Remove the iron briefly if the garment is getting too hot before continuing.

Use a tea towel or another piece of cotton cloth over the image to iron on. Do not use the iron in direct contact with the image.

Heat fix times and temperatures: Please note heat fixing times and temperatures are subject to vary depending on the accuracy of the settings in the appliance to be used. The following is a guide only:

• Cotton, calico, linen, rayon 4-5mins at 140°C -180°C

• Synthetics, nylon, polyester, tetron, acrylic 5-8mins at 115°C -130°C

It is important to remember that valuable projects always warrant a test. Heat fixing tests should always be done on the fabric to determine the temperature and time required to make the image fast (permanent) but without scorching the particular fabric. Test by heat

You’ll need to set the fabric paint with heat. In order for the paint to set permanently into the fabric, it has to be set with heat. Check ahead of time that the fabric you’re using can be treated with heat since this step ensures that your design will last much longer than without it.

SILK SCREENS

These frames are ideal for screen printing on fabric or paper. You can choose from two sizes: A4 and A3. These frames are excellent for screen printing projects! Looking for a matching squeegee? We have you covered with matching A4 and a3 PolyU rubber squeegees with moulded handle.

Silk Screen Range

SQUEEGEES

These screen printing squeegees have a wood handle and a POLYU RUBBER blade for excellent performance with Derivan screen printing frames when printing on fabric paper, cardboard, or wood. These squeegees are available in A4 and A3 sizes, and their easy-to-grip wood handles ensure a comfortable printing experience.

Screen Print Squeegee

SCREEN INK

Derivan Screen Ink is a water-based, non-toxic silk screen printing ink formulated for textiles, available in 28 colours. When applied, its superb quality and detail result from its high pigmentation. It may be used on various garments and materials, including tank tops, sweatshirts, hoodies, and t-shirts, as well as canvas and other materials. It is water-based, so it is safe for school and home screen printing projects.

Screen Ink Range

SCREEN PRINTING KITS FOR FABRIC

SILKSCREEN LIQUID STENCIL SET

Create your screen print design onto your silkscreen using the Derivan Screen Printing Stencil Set. This non-toxic water-based process makes creating your designs into screen prints a breeze. Perfect for the art studio, classroom or dining table.